What are the selection requirements for shaft machining processes?

Release time:

2024-12-09

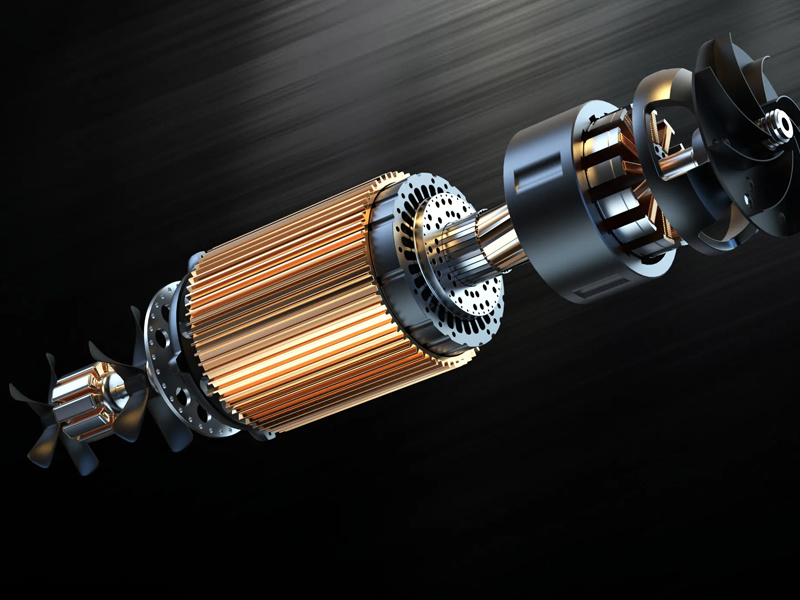

The shaft is generally manufactured from rolled round steel or forged pieces through cutting processing.

The shaft is generally made from rolled round steel or forgings through cutting processes. For shafts with smaller diameters, round steel bars can be used; for important shafts with large diameters or significant step diameter changes, forgings are often used. To save metal and improve manufacturability, large diameter shafts can also be made hollow, with welded or forged flanges. For shafts with complex shapes (such as camshafts and crankshafts), casting can be used.

1. Selection of shaft blanks

For self-locking nut shafts or shafts with little diameter variation, and less critical shafts, rolled round bars can be selected as shaft blanks; if conditions allow, cold drawn round steel can be used directly; for important shafts that bear loads, heavily loaded shafts, and step shafts with significant diameter changes, forgings are generally used; for shafts with complex shapes, cast blanks can be used.

2. Selecting shaft materials based on usage conditions

Most shafts bear both torque and bending moments, and often work under variable stress conditions, so the materials for shafts should have good strength and toughness. When used in sliding bearings, they should also have good wear resistance. Carbon structural steel is widely used, with 45 steel being common, which has excellent overall mechanical properties after tempering. Less critical shafts can also use ordinary carbon structural steels like Q235 and Q275.

3. Heat treatment and surface treatment processes to improve the mechanical properties of materials

Cold working hardening is a mechanical surface treatment process that can also be used to improve the surface quality of shafts and increase fatigue strength. Methods include shot peening and burnishing. Shot peening creates a thin layer of plastic deformation on the surface, significantly reducing surface roughness, hardening the surface layer, and eliminating micro-cracks, resulting in residual compressive stress on the surface.

Related Blogs

What are the selection requirements for shaft machining processes?

The shaft is generally manufactured from rolled round steel or forged pieces through cutting processing.

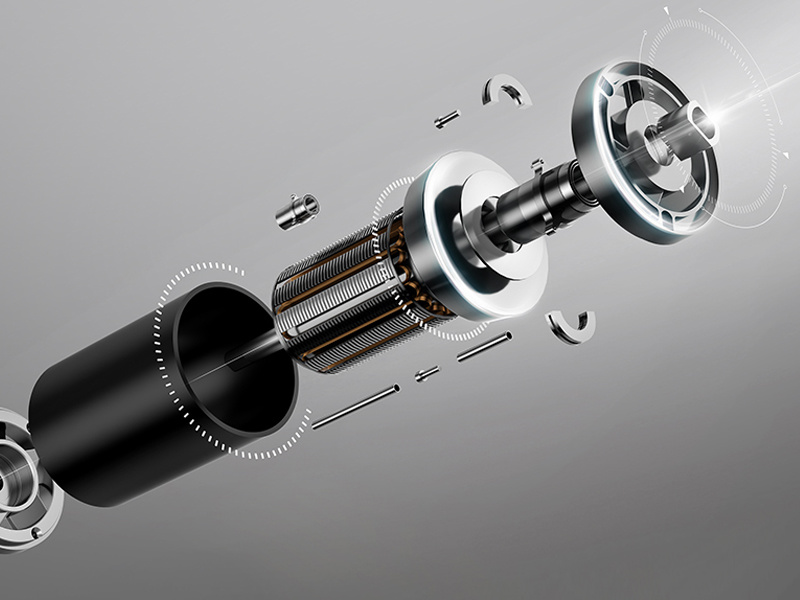

The heat generation situation of losses in the main spindle motor of new energy vehicles.

The losses of the electric spindle motor generate heat. From the basic structure of the electric spindle, it can be seen that the motor is installed inside the electric spindle.

How to extend the lifespan of industrial motor shafts?

How can we increase the lifespan of industrial motor shafts? Especially, what are effective measures to prevent current issues in industrial motor shafts?