What should be noted when processing slender shafts in shaft machining?

Release time:

2021-06-30

For shaft processing, next, we will mainly focus on understanding and getting to know the slender shafts.

For shaft processing, next, we will mainly focus on the understanding and knowledge of slender shafts in this aspect of processing. Moreover, this is an important aspect for us because it belongs to shaft processing, which is why there are the above requirements. Therefore, we will specifically explain some precautions or aspects that need attention during the processing to ensure everyone has a correct understanding.

In shaft processing, for slender shafts, if we summarize the precautions or aspects that need attention during processing, there are mainly the following points:

Aspect One: Pay attention to the clamping method of the workpiece.

Generally speaking, during the rough processing of shaft machining, due to the large cutting allowance, the cutting force on the workpiece is also significant. Therefore, for workpiece clamping, using the top clamping method and employing an elastic tailstock center can allow the workpiece to freely extend axially. However, this is not suitable for high-speed and large-scale cutting, so the clamping method should be used to avoid various issues.

Aspect Two: Use an appropriate follow tool holder.

Since the follow tool holder is an important accessory in the processing of slender shafts, it is necessary to use an appropriate follow tool holder to counteract the influence of radial cutting forces during processing, thereby reducing cutting vibration and workpiece deformation. However, it is important to note that the center of the follow tool holder should be consistent with the center of the machine tool's tailstock.

Aspect Three: If necessary, reverse feed can be used.

In shaft processing, for the turning of slender shafts, the cutting tool is often fed to create an axial elongation trend in the workpiece. However, if a clamping tool is used and reverse feed is applied, it can avoid the problem of bending deformation in slender shafts. Moreover, there are different requirements for rough and finish machining on the cutting tool, so different cutting tools should be used accordingly.

Related Blogs

What are the selection requirements for shaft machining processes?

The shaft is generally manufactured from rolled round steel or forged pieces through cutting processing.

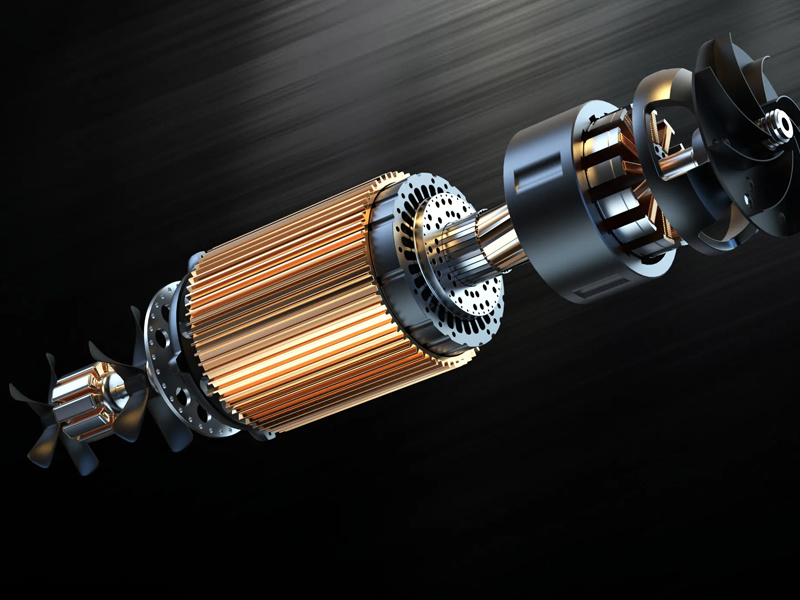

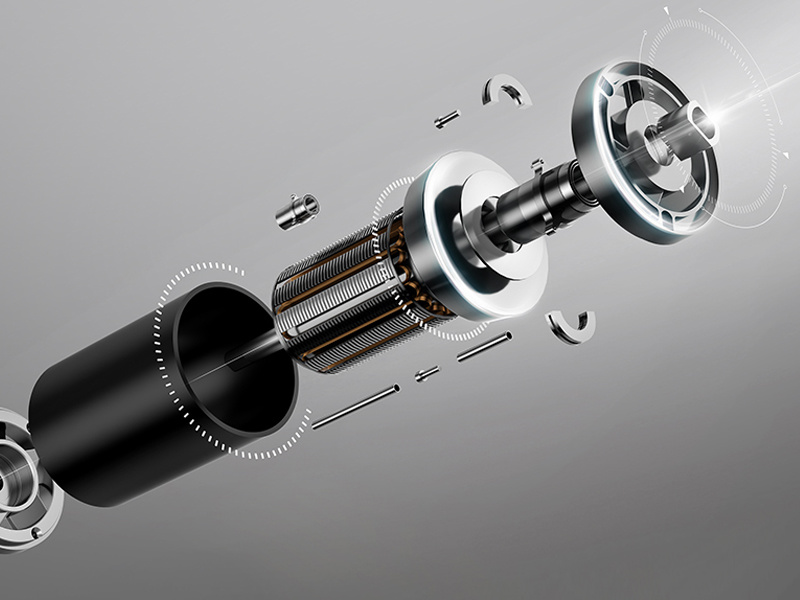

The heat generation situation of losses in the main spindle motor of new energy vehicles.

The losses of the electric spindle motor generate heat. From the basic structure of the electric spindle, it can be seen that the motor is installed inside the electric spindle.

How to extend the lifespan of industrial motor shafts?

How can we increase the lifespan of industrial motor shafts? Especially, what are effective measures to prevent current issues in industrial motor shafts?