What are the processing techniques for shafts?

Release time:

2021-06-30

The shaft, as an important component in mechanical transmission, directly affects the overall performance and stability of the mechanical system through its processing quality and precision.

The shaft, as an important component in mechanical transmission, has its processing quality and precision directly affecting the overall performance and stability of the mechanical system. Therefore, the selection and optimization of shaft processing technology are particularly important. This article will detail the types and characteristics of shaft processing technology, analyzing various technical means from traditional turning, milling, and grinding to modern CNC processing and laser cutting, aiming to provide a comprehensive reference guide for relevant practitioners.

In addition to the shaft processing technologies mentioned above, surface coating treatment of the shaft is also an important aspect that cannot be ignored. To improve the wear resistance, corrosion resistance, and anti-seizing properties of the shaft, surface treatment technologies such as carburizing quenching, nitriding, and high-frequency induction heating quenching are commonly used. Carburizing quenching can increase the carbon content on the surface of the shaft, enhancing hardness and wear resistance; nitriding can form a dense nitrided layer on the surface of the shaft, significantly improving its corrosion resistance and fatigue strength. High-frequency induction heating quenching is aimed at locally heating and cooling key areas of the shaft for hardening treatment, which not only increases the strength of the shaft but also avoids deformation issues that may arise from overall quenching. Additionally, for shafts that need to operate in harsh environments, surface coating technologies such as ceramic spraying and hard chrome plating can be used to further enhance their service life and reliability. The selection and application of these surface treatment technologies need to be comprehensively considered based on the specific working environment and performance requirements of the shaft.

Related Blogs

What are the selection requirements for shaft machining processes?

The shaft is generally manufactured from rolled round steel or forged pieces through cutting processing.

The heat generation situation of losses in the main spindle motor of new energy vehicles.

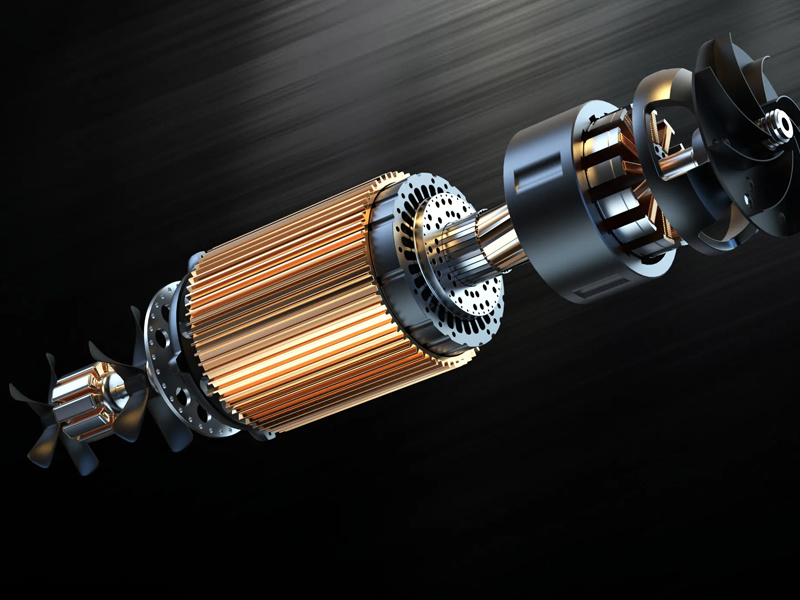

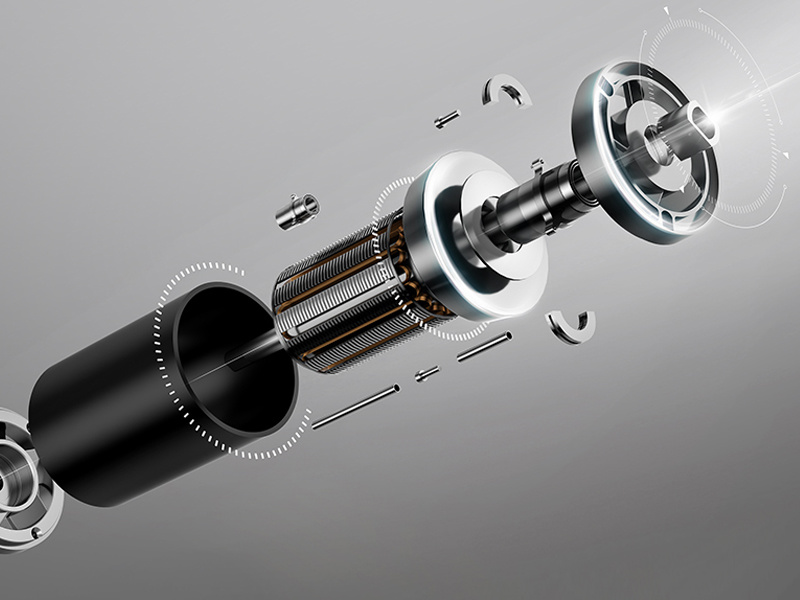

The losses of the electric spindle motor generate heat. From the basic structure of the electric spindle, it can be seen that the motor is installed inside the electric spindle.

How to extend the lifespan of industrial motor shafts?

How can we increase the lifespan of industrial motor shafts? Especially, what are effective measures to prevent current issues in industrial motor shafts?